(Note: Please know that I am an experienced DIY guy and have lived my entire life tearing into systems to figure out how they work. I would never suggest that you attempt to repair any of your home’s systems without consulting a professional and must tell you in advance that you may be held liable in the future if your work is the cause of failure.)

If you live in a hot part of the country, you probably have an air conditioner. Air conditioners have moving parts, and those parts are subject to wear and tear. Hiring a service technician is usually the first thing that you do when you have a problem, and many times it is well worth the expense. HVAC companies can and will charge a hefty price to repair problems with your A/C unit, and rightly so. Think about it. You’re calling them to alleviate the pain of a very hot home, and they’re out driving all day to homes that have no air conditioning. Who’s uncomfortable now?

If you live in a hot part of the country, you probably have an air conditioner. Air conditioners have moving parts, and those parts are subject to wear and tear. Hiring a service technician is usually the first thing that you do when you have a problem, and many times it is well worth the expense. HVAC companies can and will charge a hefty price to repair problems with your A/C unit, and rightly so. Think about it. You’re calling them to alleviate the pain of a very hot home, and they’re out driving all day to homes that have no air conditioning. Who’s uncomfortable now?

Recently, a friend of mine experienced a slight problem with her A/C unit. It was making a buzzing noise and no air was blowing. For those of us who have ever played with a TYCO race set as a child, or an electric train set, we all know that when something electric has a buzz but doesn’t do what it should, it’s probably stuck.

Sure enough, after a $79.00 service call the results were in. A fan motor was stuck. What perplexes me is the solution that was offered to pacify the problem. Apparently the technician told her that all she needed to do was unplug the unit, reach into the blower fan, move it a bit, then press the reset button.

Sure enough, after a $79.00 service call the results were in. A fan motor was stuck. What perplexes me is the solution that was offered to pacify the problem. Apparently the technician told her that all she needed to do was unplug the unit, reach into the blower fan, move it a bit, then press the reset button.

The reset button? There is no reset button, as I later discovered. It turns out that the “reset button” that the service technician was speaking of was the safety kill switch that’s disengaged when the lid to the unit is removed. It’s not a reset button. Based on what my friend had told me, there was no longer a problem, as I had not yet explored the unit to see what was actually wrong…

service technician was speaking of was the safety kill switch that’s disengaged when the lid to the unit is removed. It’s not a reset button. Based on what my friend had told me, there was no longer a problem, as I had not yet explored the unit to see what was actually wrong…

…until today. She called me frantically to let me know that her air conditioner wasn’t working again, and the solution that she had learned about from the HVAC company wasn’t working. So, I came by to discover what I had suspected all along. The motor was stuck. In fact, it had completely seized.

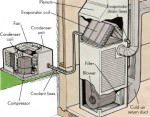

The anatomy of an air conditioner is very basic. Gas is compressed into a liquid. Compression causes friction, friction equals heat. The fan outside of your house helps vent the heat into the atmosphere. When the liquid evaporates, it cools quickly, just like sweat evaporating from your body during exercise. The cold liquid which travels to the unit inside your home is piped through copper tubes; very cold copper tubes. Blowing air over those cold tubes cools the air in your house.

The blower, a simple fan, shroud, and electric motor are the components that are responsible for moving this air.

Electric motors fail over time and eventually they stop spinning because their bearings get stuck or because the motor burns out. We called up the same service company and they quoted us $650.00 to replace the old broken motor with a new one. Too much for my taste. Especially since I had experienced the same type of problem with a condenser fan on my air conditioner years ago, which only cost me $89.00 to repair because I did it myself.

For this problem, within 4 hours I had disassembled the blower (an entire 3 parts), driven to my local distributor to purchase a new electric motor and capacitor, and re-installed the new parts. My total cost for the repair was $127.00 plus 4 hours of my time and gas. I usually consider the education part of my time value.

All in all, I’d say $50/hr is a great price compared to what would have been $162.50/hr by the HVAC company, and now I know how to do it.